Recycled Fabric

In 2022, 66% of our purchased fabric was made using recycled content (63% in 2021)

Fluorocarbons

Fluorocarbons are found in Durable Water Repellent coatings on fabrics and trims. We use fluorocarbon-free DWRs where suitable or shorter chain fluorocarbons (C6) DWRs in our more technical apparel.

Once we find an alternative that performs, we’ll switch.

We’re trying to eradicate fluorocarbons from all our products by winter 2024.

Fluorocarbons are found in Durable Water Repellent coatings on fabrics and trims. We use fluorocarbon-free DWRs where suitable or shorter chain fluorocrarbons (C6) DWRs in our more technical apparel. Once we find an alternative that performs, we’ll switch.

* Some products have since been identified with fluorocarbons in zips.

Our commitment to eradicating fluorocarbons/PFCs

Our journey to eliminate fluorocarbons from all our products by AW24 is an ambitious one, but on track. We have removed all long-chain (C8) fluorocarbons from our supply chain. However, some short-chain fluorocarbons (C6) are still needed for some of our high-end technical products. We are working with our partners to eliminate fluorocarbons from all our ranges by AW24. We have communicated progress in our 2023 Sustainability Report published June 2023

What are fluorocarbons/PFCs?

Fluorocarbons (also known as PFCs) are a category of synthetic chemicals that are used to make man-made products waterproof. They can be found in anything from non-stick cookware to takeaway boxes, carpets and toiletries. When it comes to clothing, adding fluorocarbons to a fabric means water beads on its surface and rolls off, rather than being absorbed.

How are fluorocarbons used in outdoor gear?

Fluorocarbons have numerous practical properties that make them interesting for the outdoor industry. The materials are for example:

- Water repellent

- Dirt-repellent

- Grease and oil repellent

Fluorocarbons are found in Durable Water Repellent coatings on fabrics and trims. We use fluorocarbon-free DWRs where suitable or shorter chain fluorocarbons (C6) DWRs in our more technical apparel. Once we find an alternative that performs, we’ll switch.

Are fluorocarbons harmful to the environment?

Fluorocarbons consist of carbon chains of different lengths. What makes them special is that the hydrogen atoms in these chains have been replaced by fluorine. This means that it is an artificially produced, synthetic compound.

Although these substances do not occur naturally in nature, they can now be detected everywhere on earth. Not only in heavily populated areas, but also in remote areas such as the Arctic, they can now be found. And this is a burden on the environment. Especially since the substances do not degrade on their own due to their special structure. If you want to destroy the substances, you have to burn them under extreme heat.

Because of their many benefits and ease of manufacture, Fluorocarbons are now found in many everyday products. But over time, researchers have found that the substances accumulate both in nature and in the human body.

Why do some of our zips contain fluorocarbons?

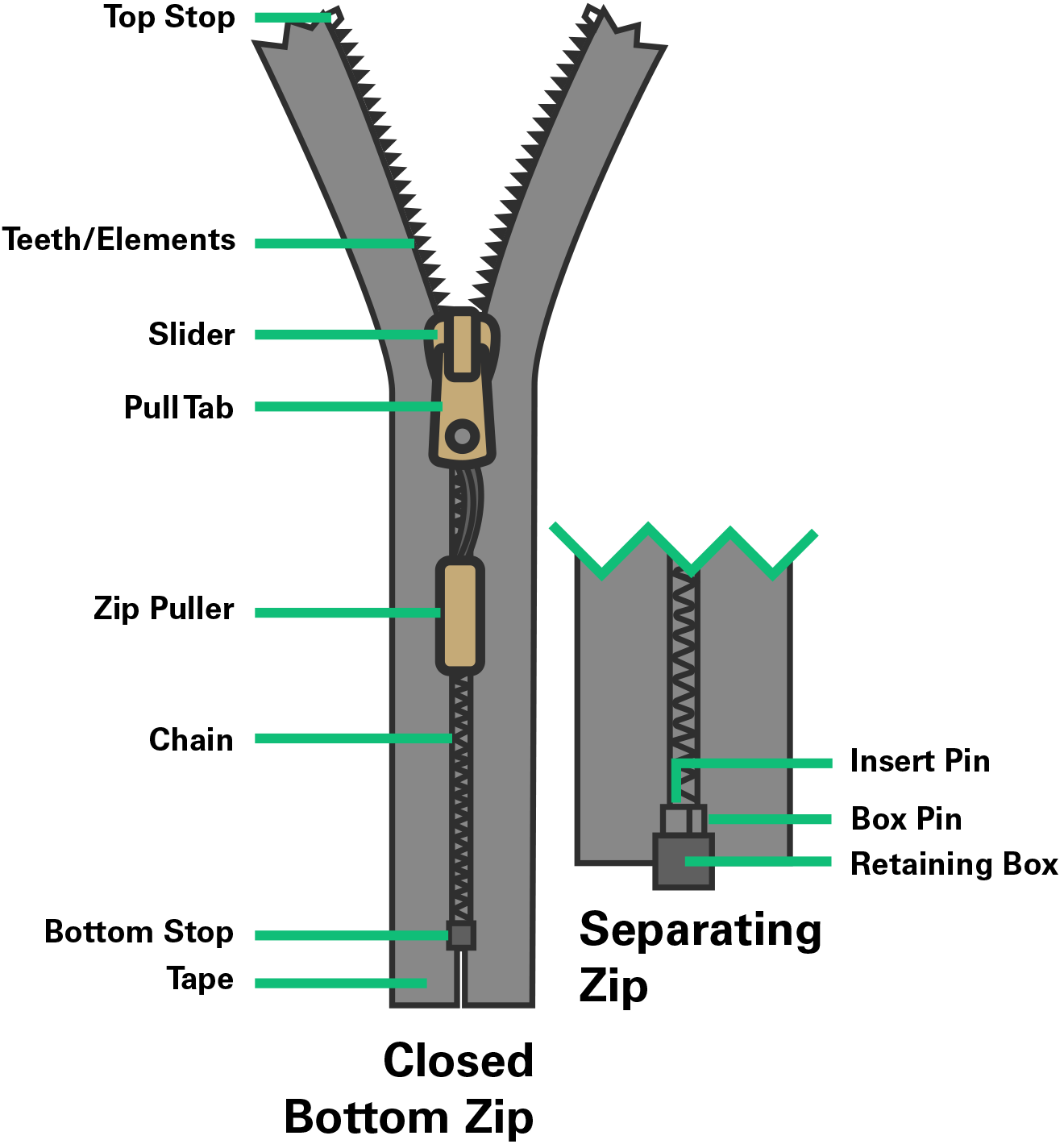

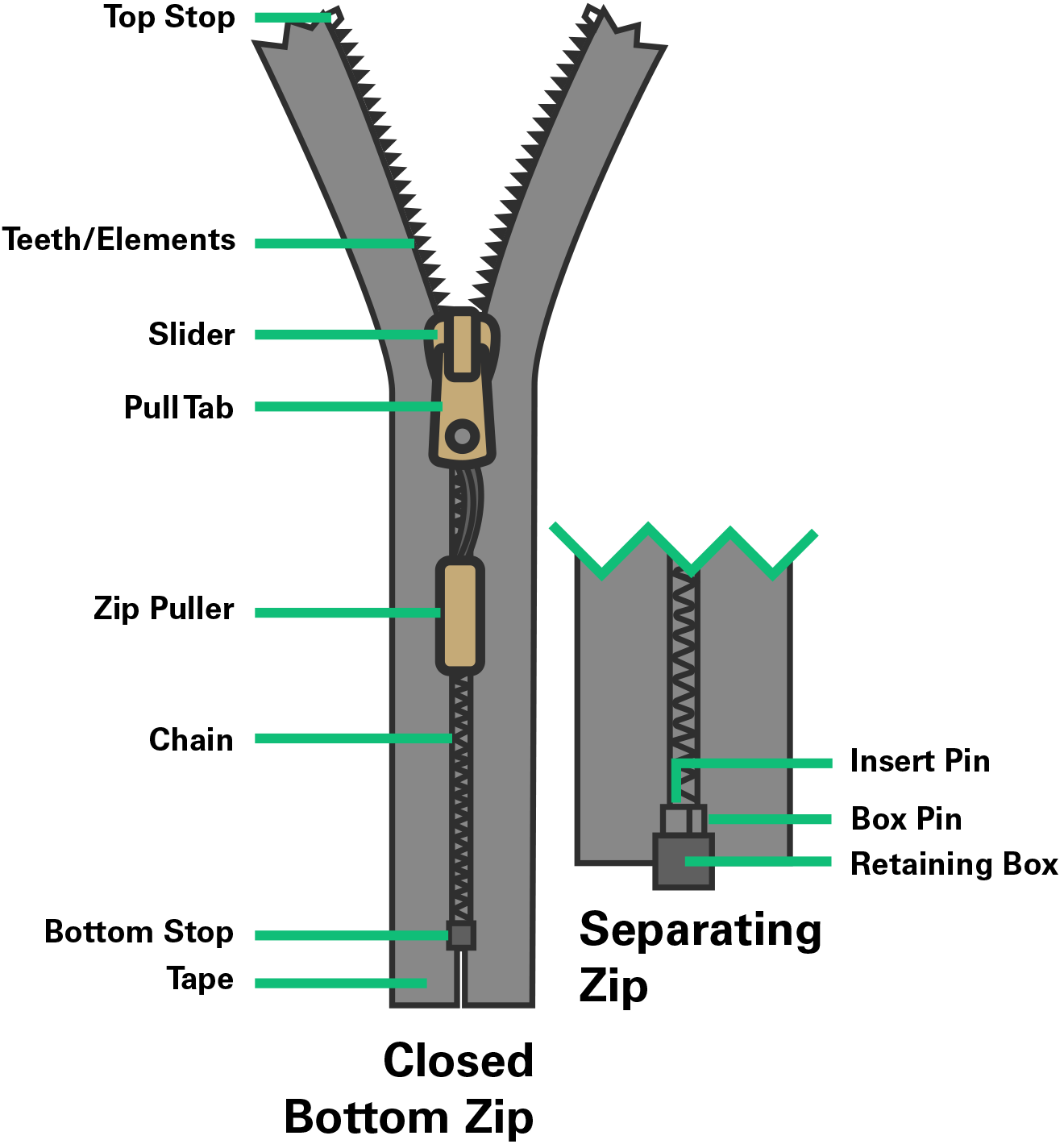

Although they might seem simple, zips are made of multiple components:

Teeth - the interlinking elements that form a chain.

Tape - the fabric used to stitch the teeth into the product.

Slider - the part that moves up and down to open/close the chain.

Stopper - the components that stop the slider at the top and bottom.

Pin Box – the box at the bottom of separating zips that aligns the two zipper halves to close.

Puller – the extra loop of cord that is added to make pulling the slider easier.

Ahead of launching Material Facts, our zip supplier informed us that, apart from some waterproof zips that use a DWR, all the zip components were fluorocarbon-free. In July 2023, as a result of additional due diligence and testing, they notified us that they had discovered fluorocarbons (specifically PTFE a legally compliant fluorocarbon) in the enamel paint they use on sliders and some pin boxes. As a global zip manufacturer, this paint can be found in zips used across multiple industries and by numerous apparel brands. We are working with our supplier to address the issue and expect to be able to switch completely to fluorocarbon-free variants by winter 2024.

The contents account for the small amounts of enamel paint used on the metal slider and pin box. The zipper teeth, tape, stoppers, and pullers do not use enamel paint. The chance of PTFE being released during use is low as enamel paint is designed to be stable and resistant to penetration.

In August 2023 we updated and reissued the Material Facts data tables for all products to account for the PTFE found in these components. As these are phased out each Material Facts table will be updated accordingly.

Responsible Design

Good design thinks about the end of a product’s life. How we reclaim the resources used and ensure as little as possible goes to landfill.

One way we’re doing this, is using Pertex Shield Revolve. It was first used in our Downpour Eco jacket in 2021. This is a mono-polymer fabric, made from one element – polyester. Making it easier to recycle once it’s no longer useable.

Microfibres: Our Commitment

✅ Test 100% of new midlayer fabrics from AW21 onwards

✅ Test baselayers from AW22 onwards

✅ Submit all TMC test data to the Microfibre Data Portal (a minimum of five test fabrics per year)

We are gradually swapping over to TMC test methodology from an alternative that was being used in some of our third-party verified labs.

*Using AATCC TM 212 test method and/or TMC test method