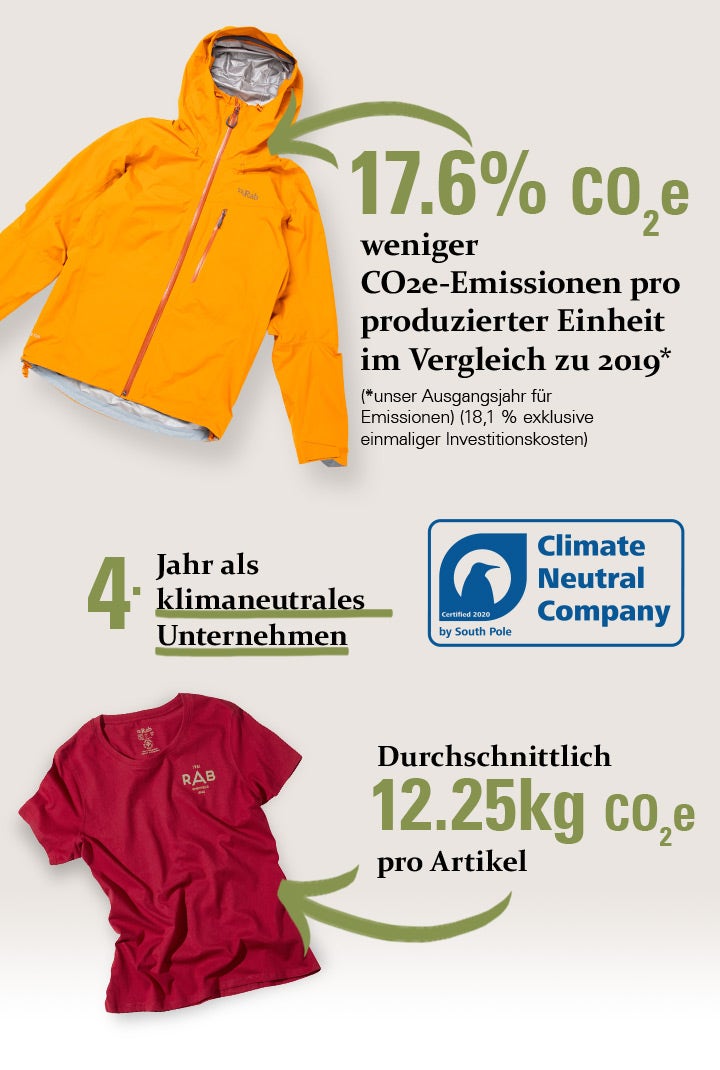

Uns verbindet eine große Leidenschaft und ein tiefer Respekt für die Natur, und so ist es nur rechtens, dass wir als Unternehmen Maßnahmen gegen den Klimawandel ergreifen, Abfall reduzieren und die Umwelt schützen.

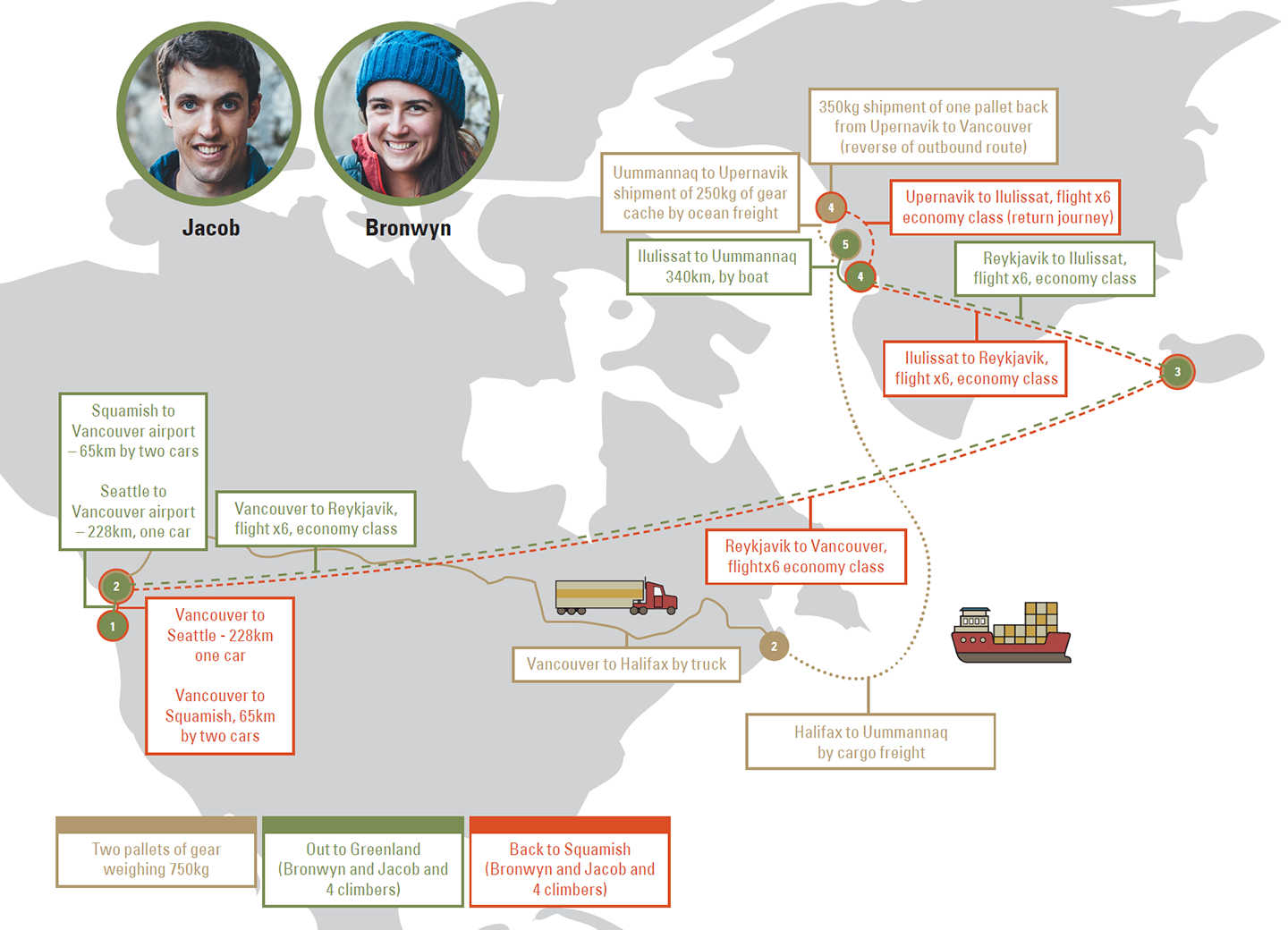

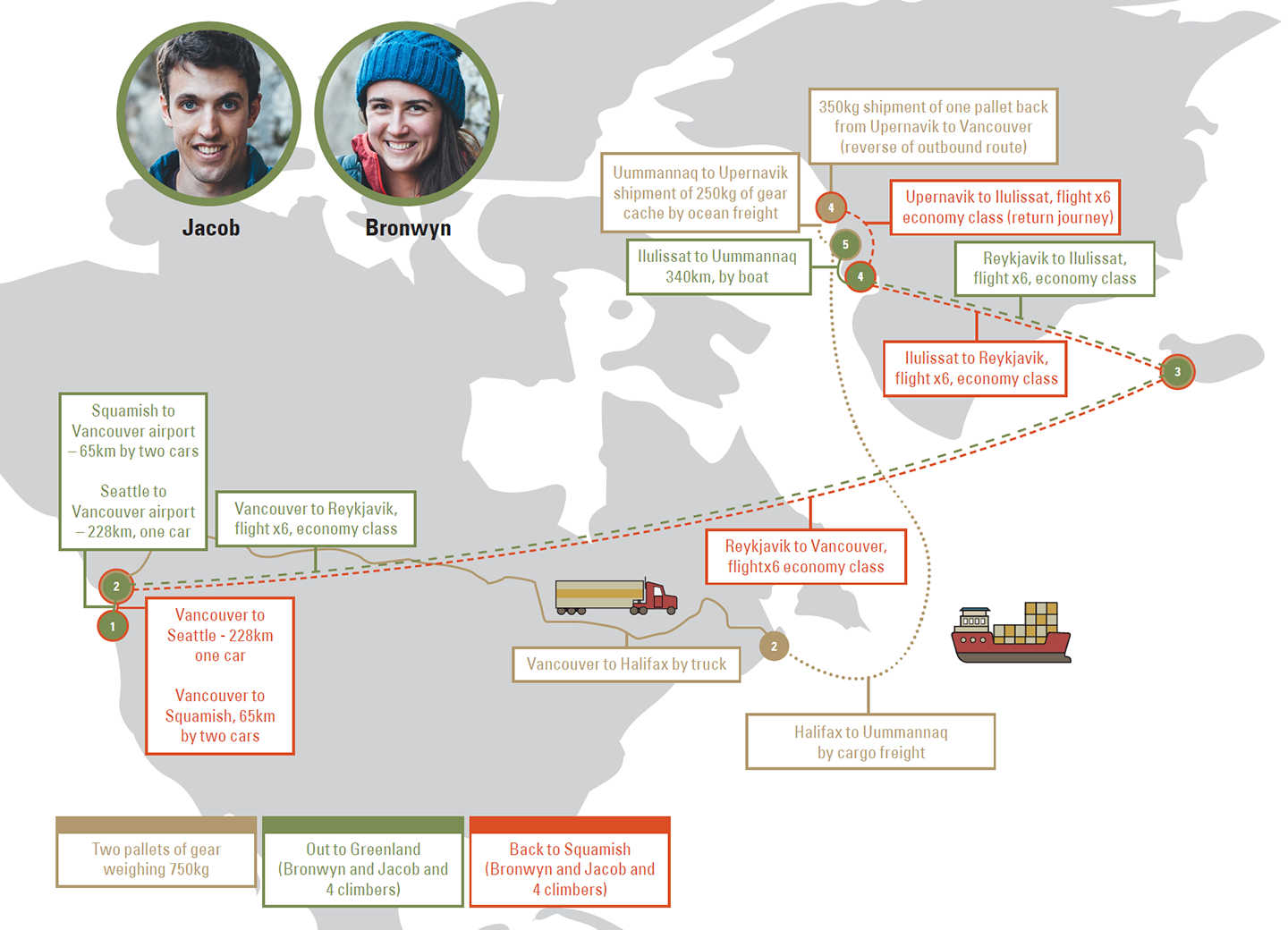

Unsere Athletenbotschafter*innen testen unsere Ausrüstung nicht nur in den unwirtlichsten Umgebungen der Welt, sie achten in unserem Namen auch mit Argusaugen auf den Zustand unseres Planeten. Sie inspirieren uns, immer besser zu werden und neue Maßstäbe in Sachen Nachhaltigkeit zu setzen. Mehr über die klimaschonenden Expeditionen unserer Athlet*innen findest du hier.

Fabrics

From climate change and the pressure on precious natural resources to fairness and opportunity for all. We aim higher, and we find a better way.

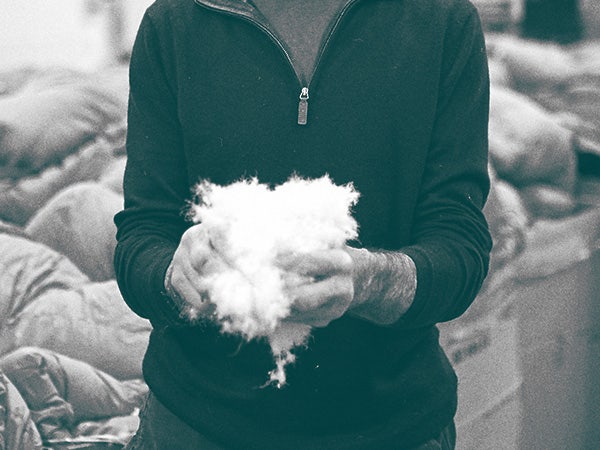

Animal Wellfare

From climate change and the pressure on precious natural resources to fairness and opportunity for all. We aim higher, and we find a better way.

Down Recycling

From climate change and the pressure on precious natural resources to fairness and opportunity for all. We aim higher, and we find a better way.

Service Centre

From climate change and the pressure on precious natural resources to fairness and opportunity for all. We aim higher, and we find a better way.